Best-of-Breed Brands and Corporate Style Services

Screen Printing

Screen printing, is a technique in which ink is transferred through a fine mesh screen to create an almost photographic style picture or pattern on a flat surface such as fabric. A squeegee is moved across the screen to fill the openings with ink. A reverse stroke is then applied to touch the material for split seconds, to wet the material with ink, before the screen is removed. One colour is printed at a time, so multiple screens can be used to produce a multicoloured design.

Pad Printing

For bespoke branding of almost any item. Also called ‘tampography’ or ‘stamping,’ pad printing is a process whereby an image is transferred onto an object through a silicone pad. One of the greatest advantages of pad printing is that the pad can virtually almost be produced in any shape, size, or density, which in turn translates into an ability to custom-brand almost any item.

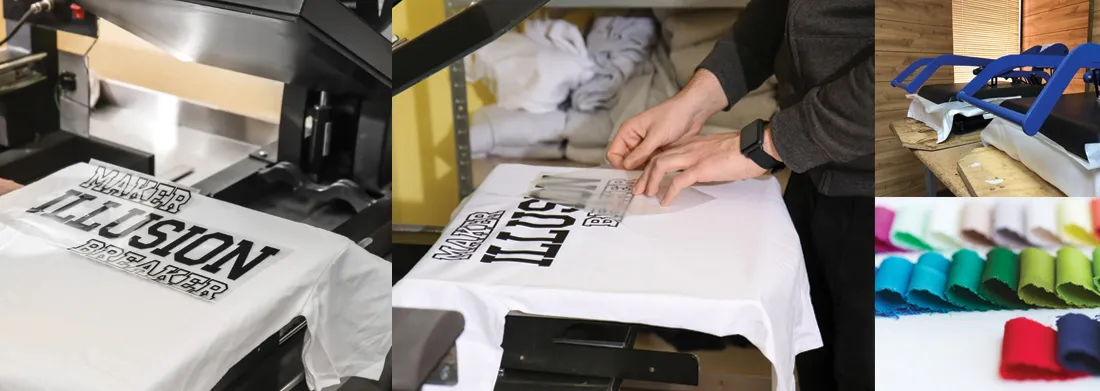

Heat Press

For imprinting vinyl or Teflon designs on material. Heat press or ‘hot press’, is a process that imprints a design or graphic onto a material such as a T-shirt for example, through the consistent application of heat and pressure, for a specific period of time. It is especially effective when you first digitally print a design on a substance such as vinyl or Teflon sheeting, cut it out and then ‘press’ it onto the item you wish to brand.

Embroidery

For detailed branding on woven fabrics and more. Embroidery is the art of sewing intricate, decorative and detailed patterns on textiles. Because of the volumes that are typically produced for promotional purposes, we make use of machinery to do the embroidery. This type of branding is ideal for apparel, caps and select bags that requires a more complex brand, logo, or image.

Embossing and Debossing

For a contemporary, yet sophisticated look. Embossing and debossing are popular printing techniques that are bound to add a modern, yet elegant twist to a branded item. The key difference is that embossing raises a shape or design from the substance in question which almost creates a 3-D effect, while debossing sinks it into the substance. This type of branding is most often used on packaging and leather items.

Sublimation

A popular option for team branding or corporate gear. This is a computerised process that imprints a digital design onto a substance, through the heat transfer of dye. This process is especially effective on material such as rugby jerseys, sportswear and corporate clothing.

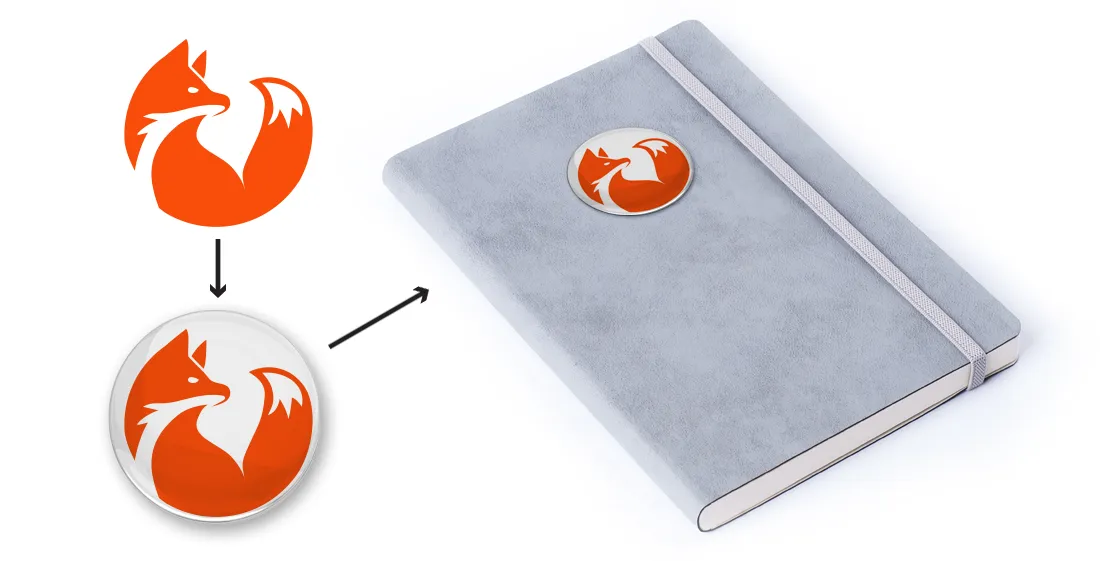

Domed Stickers

3-D like stickers for products, keyrings or magnets. Domed stickers or labels, also referred to as ‘bubble stickers,’ are stunning resin- or polyurethane-coated, raised and curved (dome-shaped) labels that create an interest- ing 3-D effect. It is ideal for items such as magnets and keyrings.

Digital Printing

For transferring of digital images on almost any substance. This is a more modern and advanced branding technique, that enables the printing of a digital image through ink transfer via inkjet- or dry toner-based printers. This type of printing can be done on almost any substance such as paper, photo paper, canvas, glass, marble, metal, and many more.

Learn about upcoming promotions and new products. Subscribe to our newsletter.

Clothing

Gifts

Bags

Display

Membership

Certified by

Proto Promotional Products

©

2026